Polyvinylchloride (PVC)

Palyvinyichloride (PVC) comes in many different forms. These different forms modify the properties to suit particular applications. Plasticisers, stabilizers, and impact modifiers can be added to produce these modifications. In general, PVC offers excellent chemical and corrosion resistance. PVC offers a major advantage over many other corrosion resistant products because it can be solvent cemented. It can also be thermally welded. This versatility in fabrication is why PVC is so widely used. The main types of PVC are:

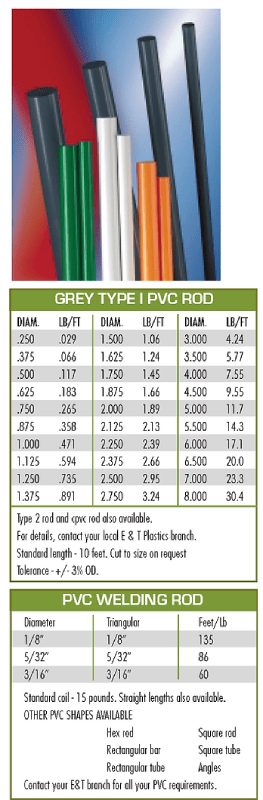

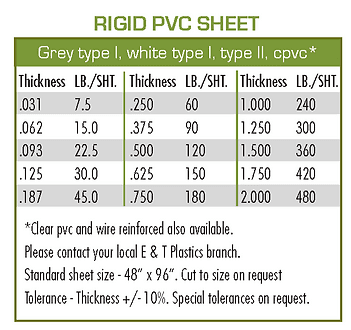

GREY TYPE | PVC – The most common type. Used for plating tanks, exhaust hoods, and scrubbers for any industry using or processing chemicals. It is NSF compliant and has a continuous operating temperature of 160°F.

WHITE TYPE | PVC – Used for aesthetic properties where white is desirable over the standard grey.

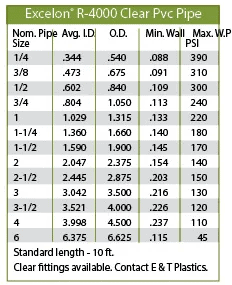

CLEAR PVC – Used for viewing windows, often in conjunction with other PVC fabrication. The advantage over other clear materials is that it can be welded to the grey or white PVC. Like the other

PVCs, it has good impact strength and chemical resistance.

TYPE Il PVC – Offers higher impact strength than the type I. it is lighter grey in color than the type I.

CPVC – This is a higher temperature material. It can be used to 200°F continuously.

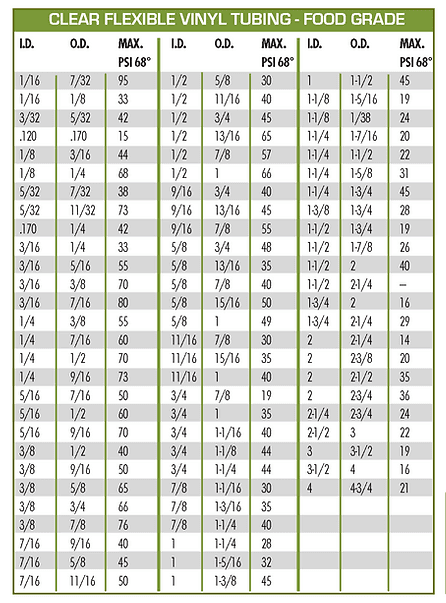

Felxible Tube | PVC