Polyethylene

The family of polyethylenes vary in molecular weigh, or densities. and exhibit varying degrees of properties. Other than UHIMW, the main types of polyethylene are LOPE & HOPE:

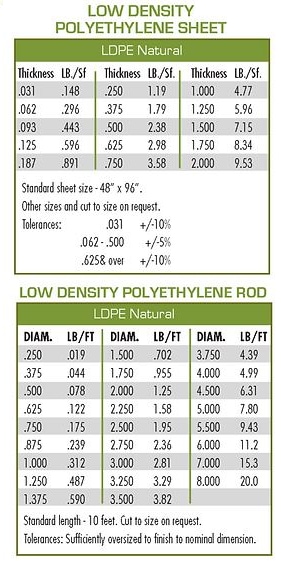

LOW DENSITY (LDPE)

LDPE offers chemical resistance, flexibility, translucency. and good thermoformability. Sheets are available “as extruded” or “stress relieved”, In stress relieved, heat is applied after the extrusion process, thus providing a flatter sheet.

LOW DENSITY POLYETHYLENE PROPERTIES

- Lightweight.

- Good impact resistance

- Extremely flexible

- Easily cleaned

The main difference between ow density and high density polyethylene is ow density’ flexibility. The main application for LDPE sheet is prosthetic devices. Most of these are either drape formed or vacuum formed.

Typical Applications:

Prosthetic Devices.

Vacuum Formed Parts

Fabricated Parts